In India we were controlling pest in wooden packing material by doing fumigation, that was in progress upto 2007 – 08. While in European countries when they were exporting material to other countries in 2005, USA, Germany, Italy, France etc countries totaly stopped using Methyl Bromide for wood packing material. In those days we were extensively using Methyl Bromide for export wooden packing. Under ISPM 15 first heat treatment plant was started in India on 01-09-2004 and slowly now there are more than 300 plants are available in India.

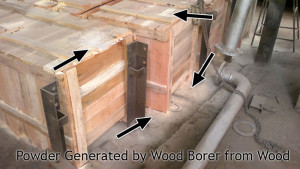

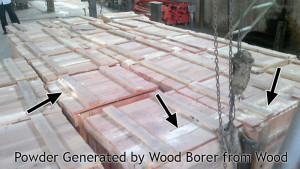

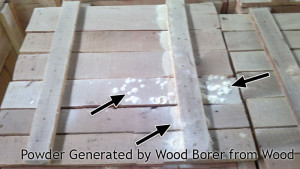

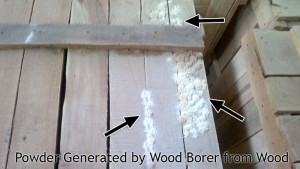

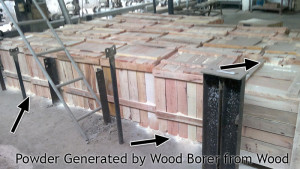

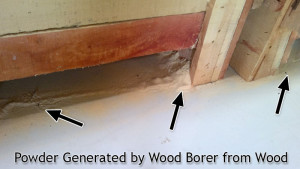

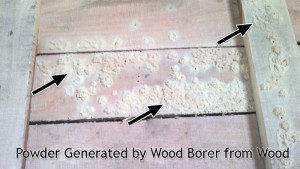

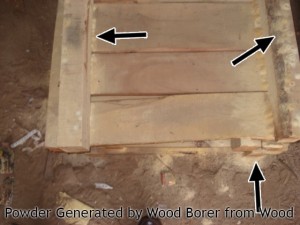

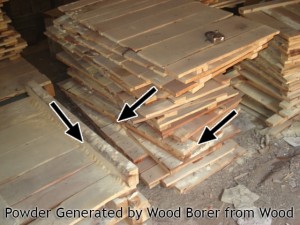

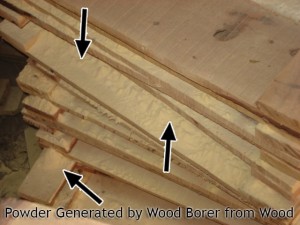

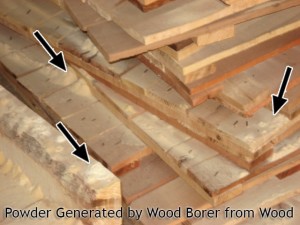

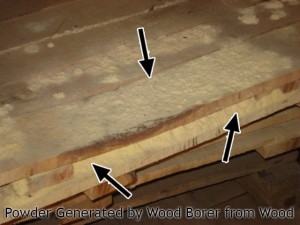

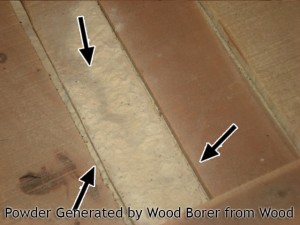

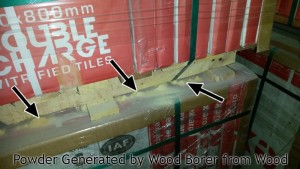

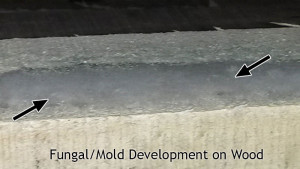

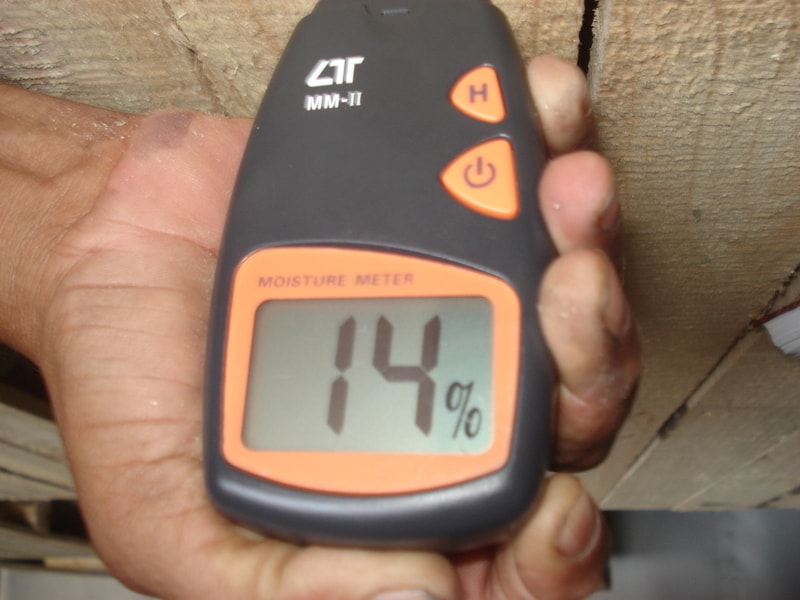

Methyl Bromide was able to control insects and pests, its eggs, larva, pupa and adult. Methyl Bromide was able to penetrate in eggs, that is why there wont be any further life cycle of insects, pests, wood borer. But there was a limitation with Methyl Bromide, it can control insects or pest from eggs to larva, pupa adult. If wood have more than 15% moisture, Then it wont give effective result, as well as a wood contain more than 35% of moisture in the wood, during export in container then it is observed a development of fungal on wooden consignment / mold in transit which was also not acceptable under ISPM 15 rules and regulation, Because it is bacterial development.

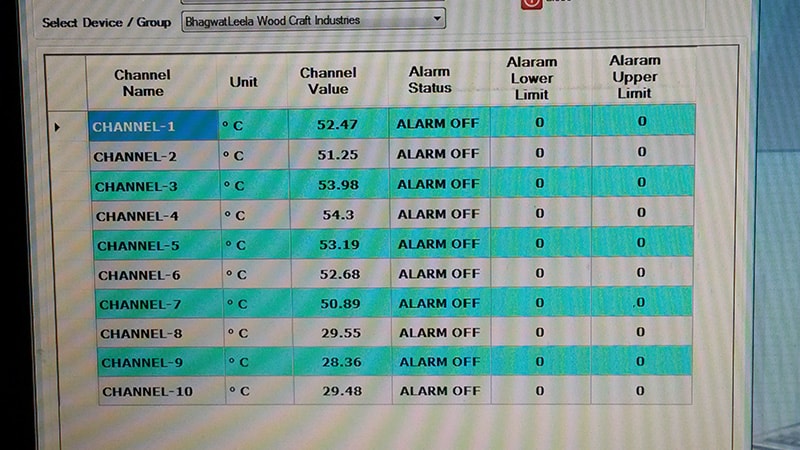

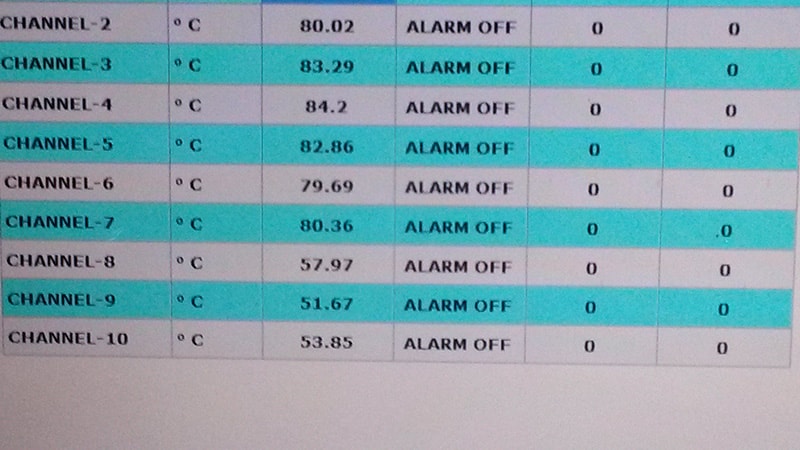

In heat treatment when core temperature is 56 degree and if plant run more than 30 – 45 minutes it will kill eggs, larva, pupa and adult insects, pests, wood borer, as well as when moisture percentage reduce to 15% from 35% it becomes very good wood and no chance of development of fungal / mold. Even there was no alternative for wood packing material except Methyl Bromide, but Methyl Bromide is depleting ozone layer that is why heat treatment is alternative to Methyl Bromide and that is why they want to reduce the use of Methyl Bromide for environment purpose.

Heat Treatment Process

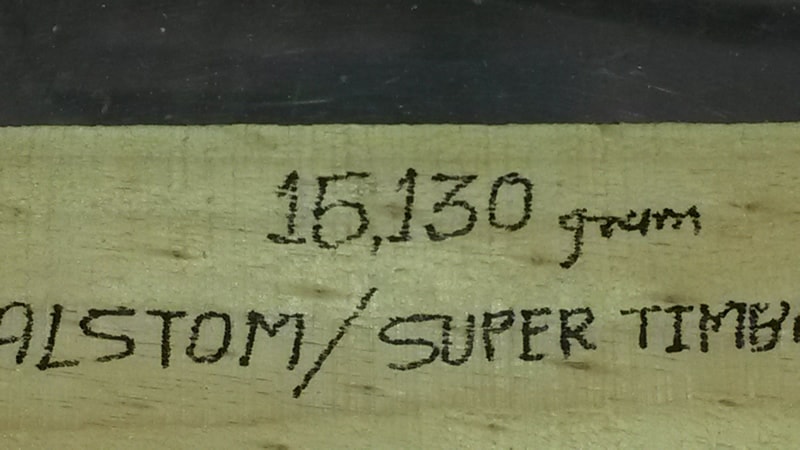

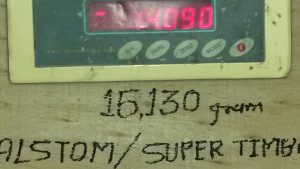

- Weighing the log wood before heat treatment.

- Weight of wooden log after heat treatment.

- Quiet advantageous, it kills insects, pests and moisture.

- Gives more strength to wood.